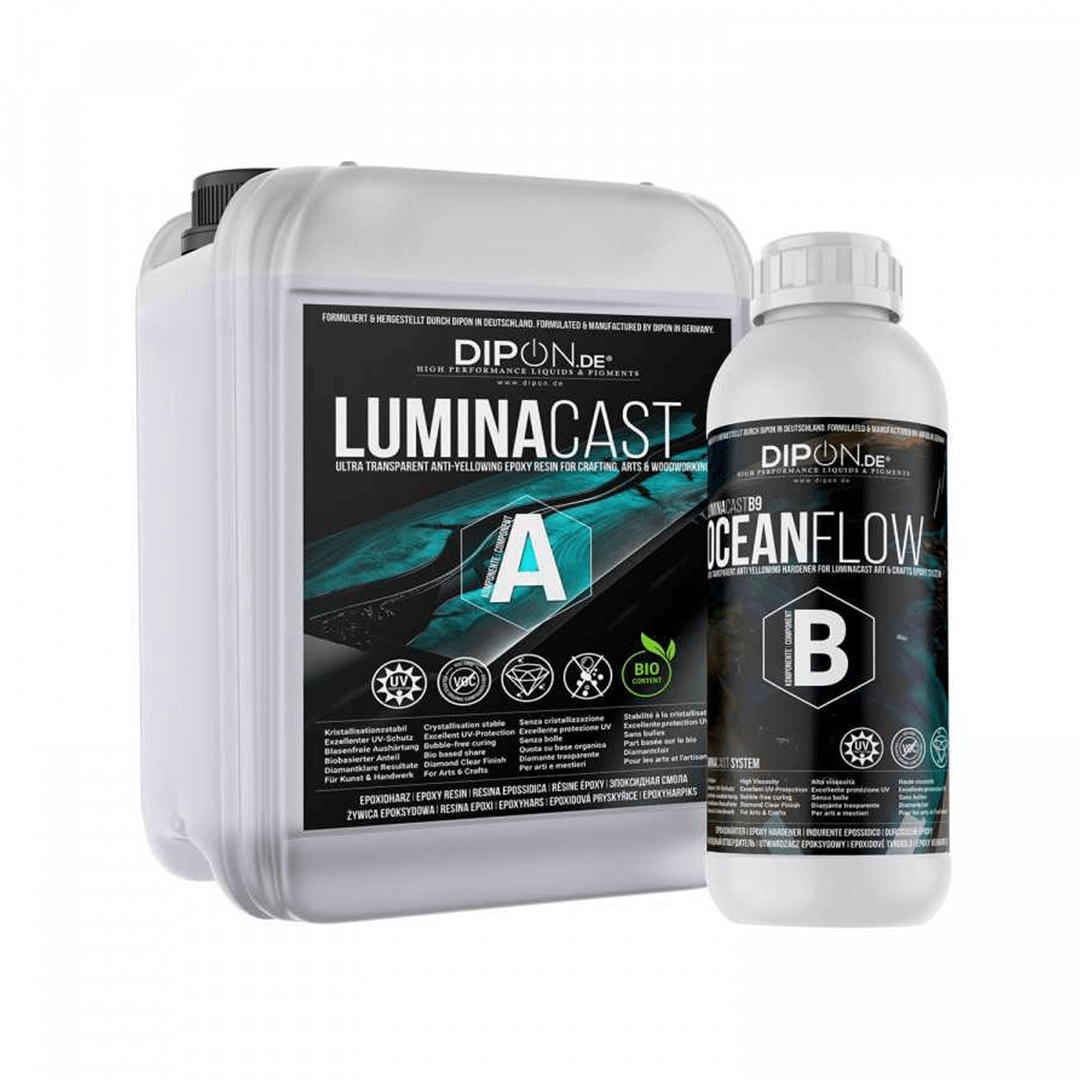

Epoxy Resin LuminaCast 9 Ocean Flow

39.38 € – 250.33 €Price range: 39.38 € through 250.33 € inc. VAT

LuminaCast 9 Ocean Flow | L transparent, pouring height up to 10 cm

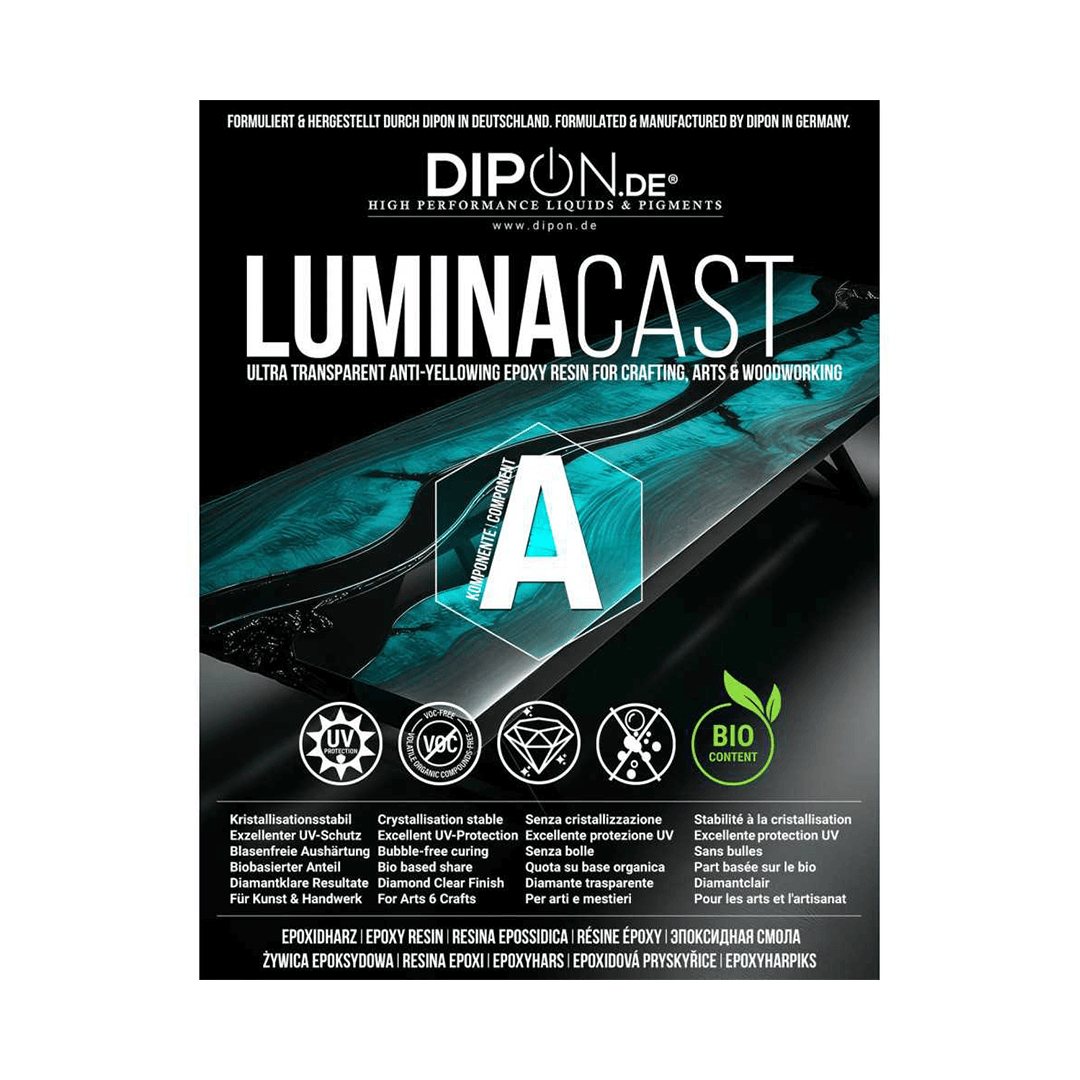

LuminaCast 9 Ocean Cast not only represents the highest quality, but is also the flagship of LuminaCast epoxy resins. Although it performs similarly to LuminaCast 8 Table Cast, LuminaCast 9 Ocean Cast features a longer processing time and slower curing. LuminaCast system with a refractive index of> 1.59, is one of the most transparent epoxy systems in the world.

Two-component LuminaCast 9 Ocean Flow A + B

- Mixing ratio 2:1 (A+B) by weight

- Layer thickness (20°C): 20 – 100 mm

- Usage time about 240 min

- Can be removed from the mold after 72-96 hours (23 °C)

- After complete chemical curing, the product can come into contact with food

- Sandable after at least 8 days (20°C).

- Creates an incomparably smooth and shiny surface.

- Advanced formulation reduces carbamate formation and ensures a flawless, smudge-free finish.

I would like more information

General features:

Crystallization is stable

Bio-based ingredients in epoxy resin

Free of CoRAP and sVHC substances

Most modern basic amines and additives, especially slightly yellowish

Mixing ratio 2:1 by weight

Processing time (23°C), 500 grams: approx. 240 min (23°C -> 40°C)

Recommended material temperature (A+B): 20°- 24°C

Recommended ambient temperature: 15 – 20°C

Dynamic viscosity (mPa*s) at 23°C: A 730 ± 50

Dynamic viscosity (mPa*s) at 23°C: B 55 ± 25

Layer thickness (23°C): 30 – 100 mm

0% VOC content

Excellent absorbency

Very little shrinkage (< 0.1%).Very low shrinkage (< 0.1%)

Compatible/suitable for working with, for example, wood, concrete, glass, metal, glass and carbon fiber fabric, natural stone, quartz sand, marble, granite.

Areas of use:

Ideal for large-format projects: LuminaCast 9 Ocean Cast is specially designed for making impressive river boards and for use in large silicone molds. It allows to pour a minimum layer thickness of 30 mm to 100 mm at 20°C. Please note that depending on the room temperature and the amount of material, higher casting quantities are possible if the room temperature is below 20°C.

Usage:

LuminaCast 9 Ocean Flow is accurately weighed by weight in a 2:1 mixing ratio in a clean container. A balance and two mixing cups are required to allow accurate weighing and mixing. Do not mix by volume as this may give an incorrect result. First, mix components A and B at a maximum speed of 300 rpm for approximately three to four minutes. The A+B mixture is then placed in a new clean container and mixed again for three to four minutes. Scrape some of the resin off the edges of the old container and drop it into the center of the new container. This process is important to get the most accurate mix possible.

Important note: Mixing transport containers (bottles/canisters) of A (resin) and B (hardener) will result in incomplete curing and a correspondingly incorrect result. The higher the room temperature and the larger the amount mixed, the faster the exothermic reaction.

Important information:

Processing time (use time) at 23°C: about 240 minutes

Mixing time: 3-4 minutes + another 3-4 minutes in a new container

Mixing ratio: 2:1 by weight

Recommended casting amount (20°C): 3.0-10.0 cm (30-100 mm)

Can be removed from the mold after (23°C): approx. 72-96 hours (10 cm, 500 grams)

The next layer can be poured after about 28-36 hours at a temperature of 20°C and 100 mm

Minimum mixing quantity: 120 grams of A+B recommended

Sandable and polished: after 8 days , 100 mm, 20°C

Safety instructions Component A:

Attention The reaction mass of 4,4′-methylenediphenyldiglycidyl ether 2,2′-[metüleenbis(p-fenüleenoksümetüleen)] bisoxirane and 2,2′-[metüleenbis(ofenüleenoksümetüleen)] bisoxirane and [[2-[p- ( oksiranüülmetoksü)bensüül] Phenoxy]methyl]oxirane oxirane, mono[(C12-14-alkyloxy)methyl]derivative Methyl 1,2,2,6,6-pentamethyl-4-piperidyl sebacate and bis(1,2,2,6,6-pentamethyl -4-piperidyl)sebacate

Hazard statements: H315 Causes skin irritation. H319 Causes severe eye irritation. H317 may cause an allergic reaction to your skin. H412 Toxic to aquatic life with long lasting effects.

Precautionary statements: P101 If medical attention is needed, have container or label at hand. P102 Keep out of reach of children. P103 Read all instructions carefully and follow them. P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove all contact lenses if possible. Continue rinsing. P310 Call a POISON CENTER/doctor immediately. P321 Special treatment (see on this label). P330 Rinse mouth. P362+P364 Remove contaminated clothing and wash before reuse. P501 Dispose of contents/containers in accordance with local/regional/national/international regulations.

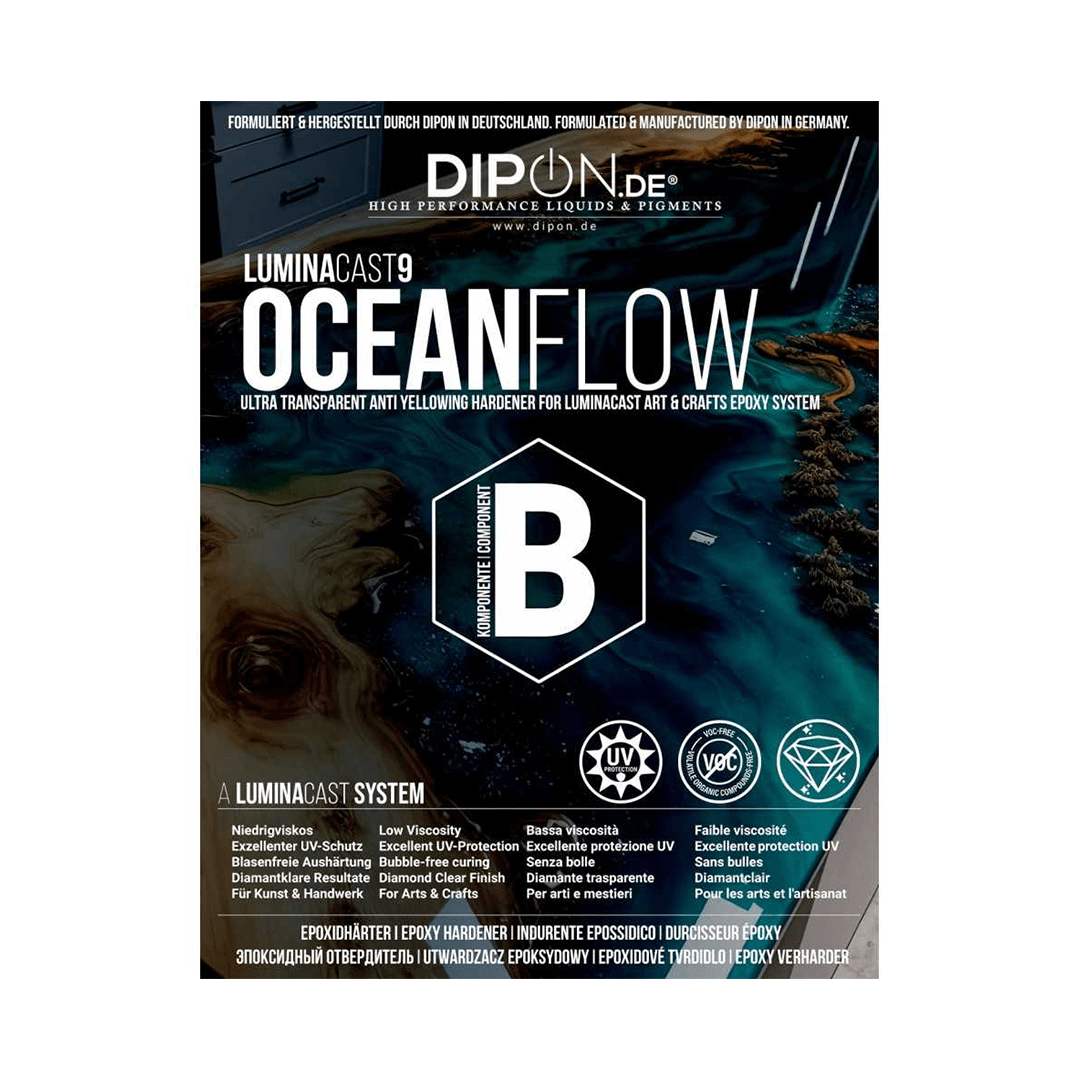

Safety instructions Component B:

Danger Contains: Trimethylolpropane-poly(oxypropylene)triamine, hydrocarbons, C9-unsatd., polymerized

Hazard statements: H302+H312 Harmful if swallowed or in contact with skin. H314 Causes severe skin corrosion and eye damage. H317 May cause an allergic skin reaction. H411 Toxic to aquatic life, long term effects.

Precautionary statements: P101 If medical attention is needed, have container or label at hand. P102 Keep out of reach of children. P103 Read all instructions carefully and follow them. P303+P361+P353 IF ON SKIN (or hair): Take off immediately all contaminated clothing. Wash the skin with water

Product features:

Mixing ratio: 2:1 by weight

Crystal clear shine, unrivaled transparency – a finish that flawlessly highlights the beauty of your work.

Responsibly produced: All LuminaCast products, including this one, consistently avoid any substance on the CoRAP or sVHC list.

Excellent flowability: The low viscosity of LuminaCast 8 Table Flow allows the resin to penetrate even the smallest cracks.

Premium UV Protection: The integration of UV absorbers and HALS additives ensures that LuminaCast offers your work the best possible protection against yellowing and UV damage.

Ideal for larger projects: optimized for furniture manufacturers, including table casting, lamps or interior elements that require a higher casting height.

Gloss: LuminaCast provides an incomparably smooth and glossy finish

Maximum durability: Our advanced formula minimizes carbamate formation for a flawless finish.

Environmental responsibility: more than 70% of our raw materials are bio-based.

Long-lasting shine: thanks to our top-quality formula, your work will remain bright and unchanged for a very long time

Every product produced and tested in our own factory meets strict quality and inspection standards.

[või duši all]

. P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. If possible, remove all contact lenses. Continue rinsing. P310 Call a POISON CENTER/doctor immediately. P321 Special handling (see on this label). P362+P364 Remove contaminated clothing and wash before reuse. P405 Keep locked up P501 Dispose of contents/containers in accordance with local/regional/national/international regulations.

Manufacturer: DIPON.DE Removable Automotive Coatings GmbH & Co. KG, Germany

| Weight | N/A |

|---|---|

| Brand | |

| Quantity |

1,5 kg ,4,5 kg ,10.5 kg ,12 kg ,15 kg |

| Color |

Transparent |

| Pouring thickness |

Up to 10 cm ,Food safe |

Purchases made in the Eriart e-store can be sent to SmartPOST, Omniva or DPD parcel machines or with Itella and Omniva couriers. We ship to Estonia, Finland, Latvia and Lithuania.