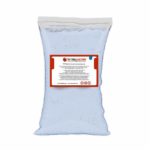

3D ALGINAT CAST BLUE PROFESSIONAL powder for hand and foot impressions

18.90 € – 57.90 €Price range: 18.90 € through 57.90 € inc. VAT

3D ALGINAT CAST BLUE PROFESSIONAL Powder – for taking impressions of hands and feet. A skin-friendly powder that can be used to create a moulding compound for fingerprints, handprints, footprints or any other part of the body. The product is harmless, skin-friendly, breathable and reacts with water, initially forming a gel-like substance, but dries to a solid mass when exposed to air. Unlike other moulding materials, an imprint can be made in a very short time.

Mixing ratio: 1 part 3D ALGINAT CAST BLUE PROFESSIONAL powder and 4,4 parts water. For example, 100g powder and 440g water.

Cost: Depending on the container: a child’s hand – up to 500g powder, an adult’s hand – 1-1.5 kg, 2 full adult’s hands – 1-2 kg, a family’s hands (3-4) – 1-2 kg.

I would like more information

3D ALGINAT CAST BLUE PROFESSIONAL is a high quality natural product based on algae, designed for the production of original models and precise moulds for hobby and professional use. Ecologically harmless, non-toxic natural product.

Technical data (room temperature approx. 22-23°C)

Hardening (water temperature 13°C): 4 – 7 min.

Hardening (water temperature 23°C): 3 – 5 min.

Processing time (water temperature 13°C): 120-150 seconds

Processing time (water temperature 23°C): 60-90 seconds

More info:

*Do not pour the alginate directly into the epoxy resin *A respirator can be used to mix the alginate and water *Once the alginate has been mixed with water, you can gently tap it against the counter for 10-20 seconds or drum the container with your hands (before placing the object in the alginate) to reduce bubbles *Before pouring the plaster or other material into the mould, make sure that no water has collected at the bottom of the alginate mould. If there is, remove excess water by gently tilting the mould. *Alginate must not be mixed with other materials! *Not edible material!

Usage:

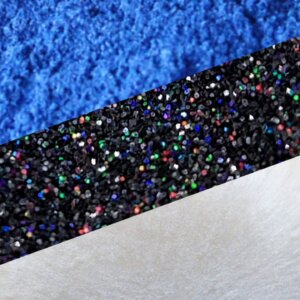

Prepare a container, such as a bucket, with the required amount of cold water (approx. 12°C-14°C). Note: When using warm water (e.g. approx. 23-25°C), the processing time is reduced to approx. 60-90 seconds and the hardening takes about 3-5 minutes. Now carefully pour the 3D Alginate Cast Blue Professional powder into the container. Tip: It is advisable to add the alginate powder in batches to reduce the formation of lumps. The powder is stirred in water for about two minutes, for example with a whisk or a suitable mixing stick. After a homogeneous mass has been formed, tracing (e.g. from the hand) can be started. Leave your hand in 3D Alginate Cast Blue Professional for about 3-5 minutes, as still as possible. The hand should not come into contact with the mould inside the alginate. The colour changes from purple (liquid) to light blue (hardened) as it hardens. Now carefully pull your hand out of the tracing material. Tip: to facilitate removal from the material, we recommend using Vaseline, which is applied before placing the hand in the gel fluid. Tip: It is advisable to mix a small sample to familiarise yourself with the material.

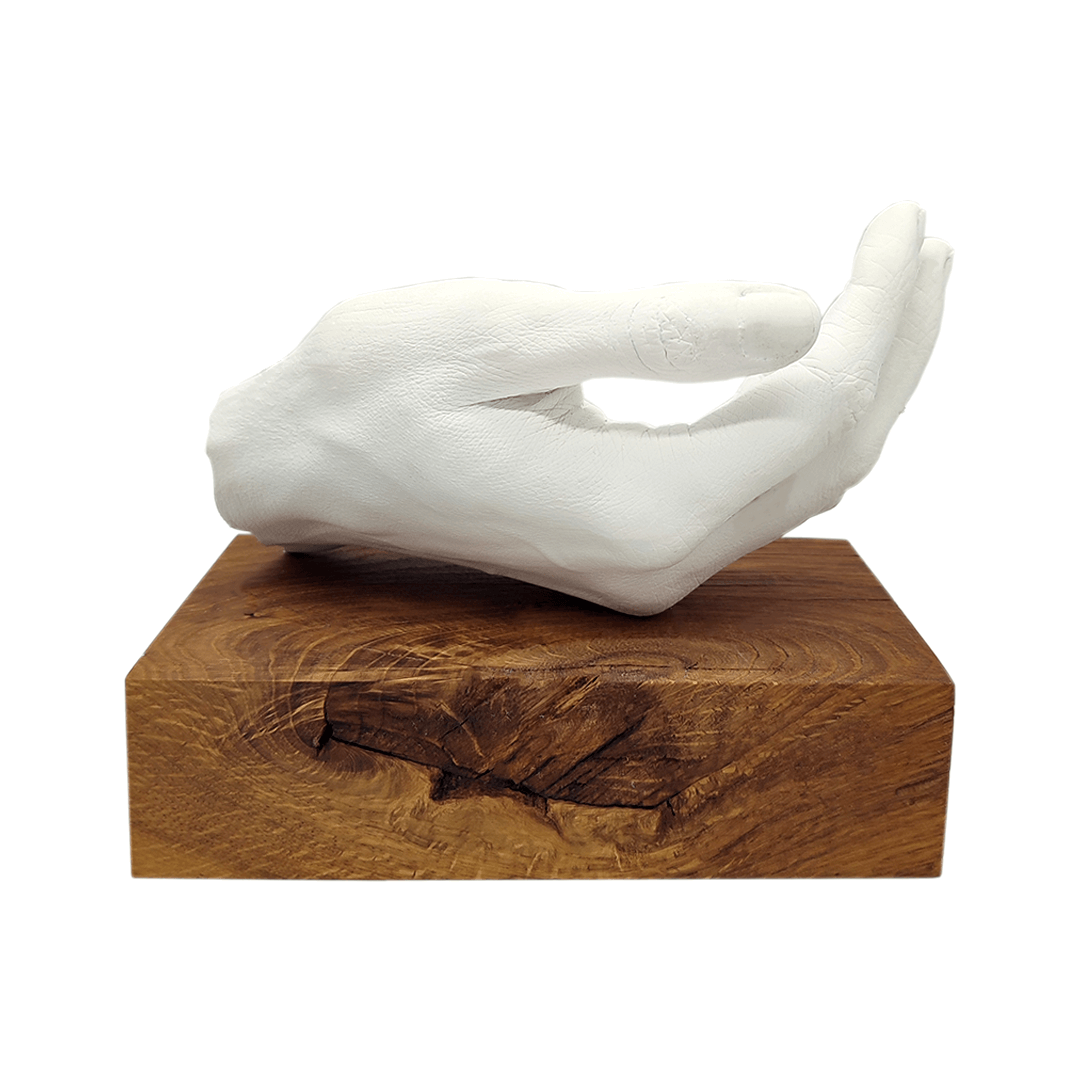

In order to obtain the desired impression of the base material, in the next step, you should mix the casting powder with the used object in the appropriate proportion and pour it into the now solidified 3D Alginate Cast Blue Professional moulding mix. After the mould or casting powder has solidified, remove the alginate from the mould and carefully tear off the pieces until the mould is free from residual alginate. Residue can be removed, for example with a brush, so that once the moulding is completely dry, the finished item can be used as a decorative element or further decorated with acrylic, epoxy resin or another material.

| Weight | N/A |

|---|---|

| Quantity |

0,5 kg ,1 kg ,2 kg |

Purchases made in the Eriart e-store can be sent to SmartPOST, Omniva or DPD parcel machines or with Itella and Omniva couriers. We ship to Estonia, Finland, Latvia and Lithuania.