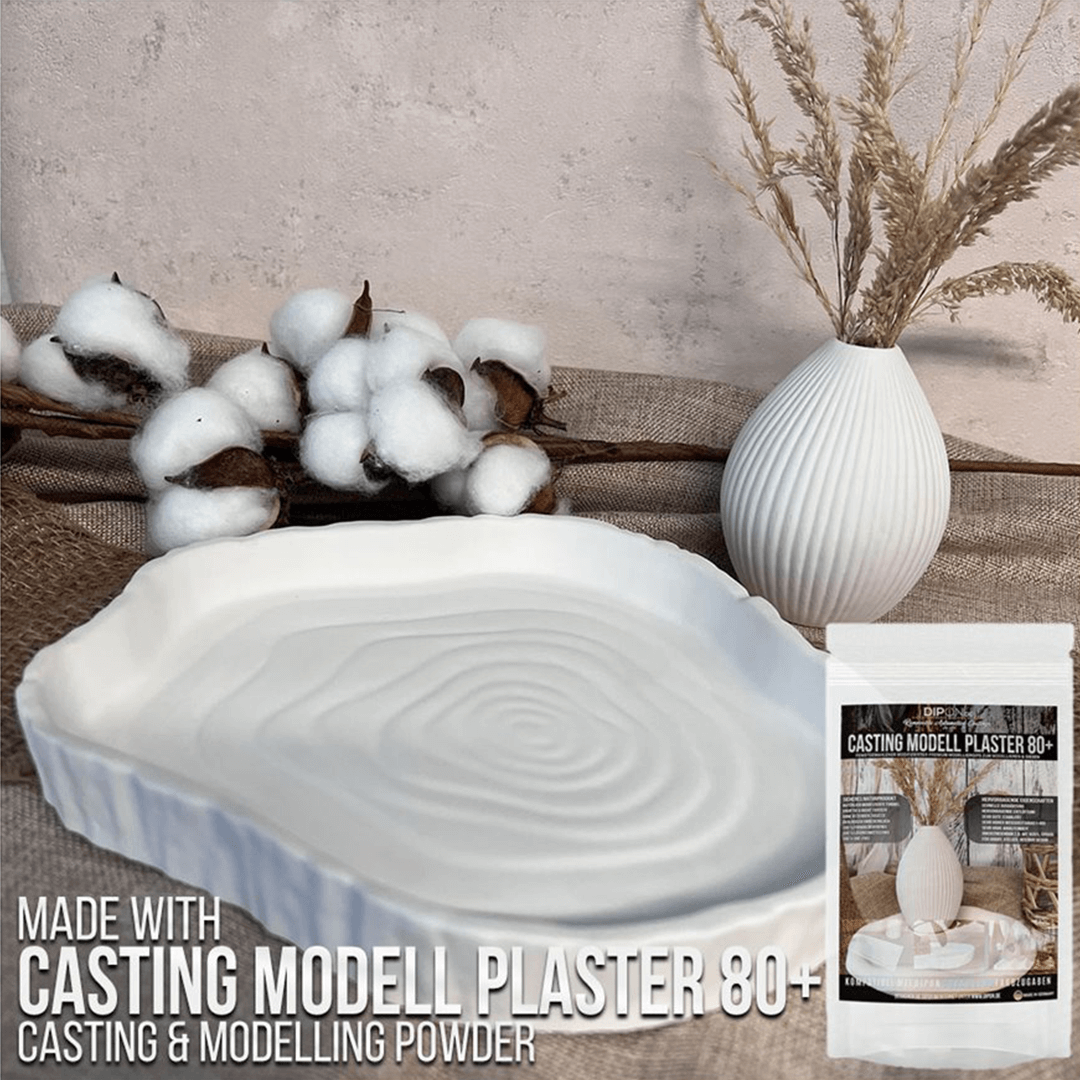

DIPON® Casting Model Plaster 80+, gypsum powder for modeling and casting

8.20 € – 26.60 €Price range: 8.20 € through 26.60 € inc. VAT

Casting Model Plaster 80+ is a particularly high-quality finely ground modified natural plaster for modeling and casting. The product is ecologically harmless, non-toxic and 100% formaldehyde- and solvent-free. DIPON® Casting Model Plaster 80+ impresses with its fast curing, good working time, very good stability and excellent air bubble removal. The product is intended for creative work, in the hobby and professional sector, such as teaching and research, handicrafts and artistic reproduction, plastering and application work, model and mold making or interior restoration work.

I would like more information

DIPON® Casting Model Plaster 80+ can be painted over with epoxy or polyurethane resins, varnishes or acrylic paints.

Mixing ratio:

- The mixing ratio of DIPON® Casting Modell Plaster 80+ for modeling is 100 grams of Casting Modell Plaster 80+ and 50-60 grams of water.

- For casting , it is recommended to mix 100 grams of DIPON® Casting Modell Plaster 80+ and 65-70 grams of water.

Instructions for use:

Use only stainless steel tools and clean tools with water immediately after use. The ambient air temperature should not fall below 4°C. Prepare the required amount of water and slowly add DIPON® Casting Model Plaster 80+ gypsum powder. Wait for 90 to 120 seconds, then mix carefully for about 2-4 minutes until a homogeneous uniform mass is obtained. Shake, tap the dishes so that air bubbles rise to the surface. The casting can be removed from the mold 30-60 minutes after months of attention, the degree of hardness has not yet been reached and the object may be fragile. Complete drying after 24 hours . The white tone increases as the material dries. Caution: Do not pour into the toilet or drain – risk of clogging! Do not inhale or swallow the powder!

Mixing ratio: Depending on the mixing ratio, a creamy or runny consistency can be achieved.

Creamy consistency (for modeling) 1 part by weight of powder + 0.5-0.6 parts by weight of water (e.g. 100 grams of Casting Model Plaster 80+ and 50-60 grams of water)

Flowing consistency (for molding, e.g. silicone molds) 1 mass part of powder + 0.65 – 0.7 mass part of water (e.g. 100 grams of Casting Model Plaster 80+ and 65-70 grams of water)

General features:

Fine-grained and naturally white. This makes Casting Model Plaster 80+ extra fine grained and gives an extra fine creamy consistency when mixed.

Manufactured in Germany according to strict national safety and quality standards.

Ecologically harmless

Non-toxic

Without corrosive additives

100% formaldehyde free

100% solvent / VOC free

Can be combined and/or painted over with resins, varnishes or acrylic paints after drying

Areas of use:

Making models and molds (casting, molding, etc.)

Perfect for working with DIPON® Alginate powder

In restoration works

Artistic reproduction, plaster and applied work

Model and mold making

Suitable for teaching and research

Suitable for use by children under adult supervision

Technical data:

Start of hardening: 15 ± 5 minutes

End of stiffness: 36 ± 8 minutes

Brightness level ≥ 82

Bulk density: 900 ± 30 kg/m³

Degree of hydration: ≥ 84%

Flexural strength: ≥ 3.8 N/mm²

Compressive strength: ≥ 12 N/mm²

Brinell hardness: ≥ 15 N/m²

Swelling: approx. 1.8 mm/m

Sieve residue 100 μm: max 2.5% / 200 μm_ max 0.1%

More info:

Do not pour down the drain or toilet. Danger of clogging!

Do not inhale or swallow the powder!

Child friendly, always use under adult supervision!

| Weight | N/A |

|---|---|

| Quantity |

1 kg ,2.5 kg ,5 kg |

| Brand |

Purchases made in the Eriart e-store can be sent to SmartPOST, Omniva or DPD parcel machines or with Itella and Omniva couriers. We ship to Estonia, Finland, Latvia and Lithuania.